TECHNOLOGIES

Patents and New Technology

With regards to the origin of coal, during the volcanic period of the Earth, acidic flooding was caused by the smoke generation of sulfur oxides. The trees that were swept by the flood were subsequently carbonized due to dehydration by sulfuric acid, which in turn caused the woody parts to become carbonized.

The coal buried by each variation is found with the fossils of protozoa, and it is presumed that microorganisms were proliferated by various minerals and nutrients present in low-grade coal with a low degree of carbonization.

Therefore, by using such low-quality coal to settle with an acidic liquid, impurities and pollen present in the coal are removed and porous is formed.

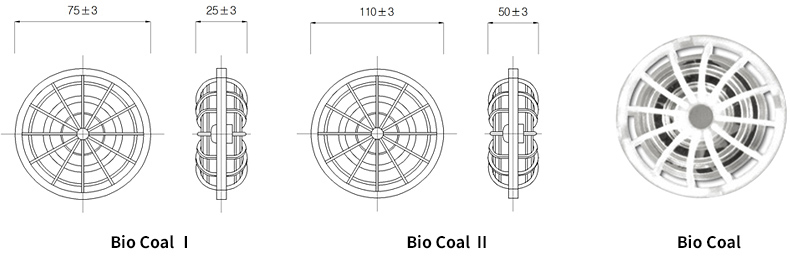

It can be inhabited by microorganisms, and after this process, it becomes coal. This activated coal is stored in grid-type high-density polypropylene cases, etc., and is referred to as bio coal (trademark registration No. 218151).

Specifications and properties

| Classification | Material | Specifications | Remarks |

|---|---|---|---|

| Bio Coal Ⅰ | HDPP | 75A x 25H | Wastewater, sewage, livestock manure, high-concentration wastewater, etc. |

| Bio Coal Ⅱ | HDPP | 110A x 50H | Wastewater, sewage, manure septic tank, etc. |

Principle of Technology

By increasing the deposit amount and by the physical and chemical role of coal, which is the filling material, the oxidation rate of organic matter and ammonia nitrogen is about 2 to 5 times faster than normal biological reactions; however, it also decomposes substances classified as non-degradable.

Technology method description

Bio Coal & Purge Method

Bio Coal

|

|

PURGE

|

Features of technology

- Excellent nitrogen removal.

Up to 99.99% of organic NH3-N can be oxidized - Phosphorus can be removed in the aeration tank without impacting microorganisms.

- Possible to double the raw water throughput without adding facilities.

Maintains 20,000ppm of MLSS of bio coal - High color, odor and harmful gas removal efficiency.

Even if only bio coal is filled, chromaticity, odor and harmful gas removal efficiency is more than 50% higher than that of other biological treatments.

In the case of influent water with high chromaticity, the desired chromaticity can be maintained simply by injecting the purge. - As the capacity of the aeration tank is minimized, it is easy to increase the throughput of existing facilities, and it is economical as it is stable against fluctuations in the flow rate and water quality.

- Maintenance costs reduced by 50% compared to other methods.

- The life of the filler is semi-permanent.

- Excellent for heavy metal treatment.

Ions such as Cr+6, Cd, Cu, etc. generated from self-cleaning action and substitution reaction also treat CN-, etc.

Certification No.

- Trademark Registration No. 218151

- Patent No. 058630