TECHNOLOGIES

Patents and New Technology

NPA

(Nitrogen and Phosphorus Removal using Aluminum alloy)

(Nitrogen and Phosphorus Removal using Aluminum alloy)

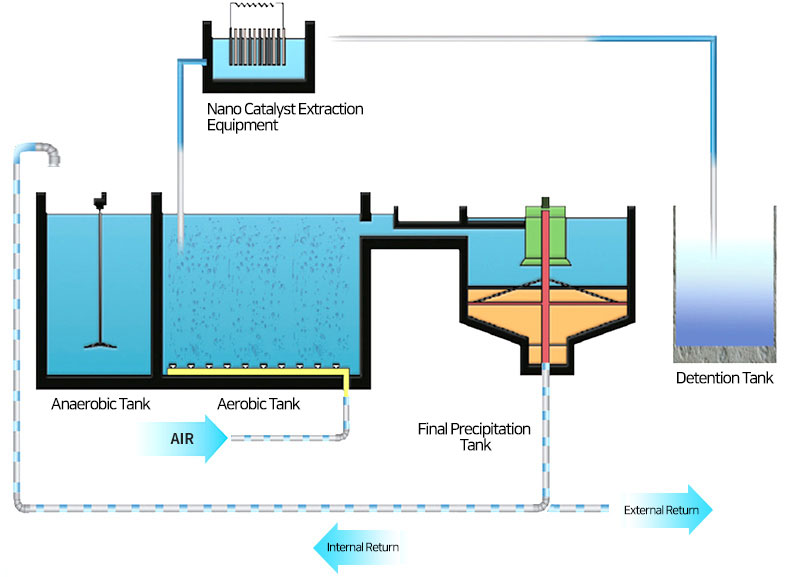

This is a sewage treatment technology that removes phosphorus caused by aluminum nanoparticles from the electrode plate by immersing the aluminum nanoalloy plate to which the rated direct current voltage is applied to the nanoprecipitation equipment, which is an electrolysis tank, through the process consisting of an anoxic tank, aerobic tank, and a nanoprecipitation equipment comprising aluminum-iron alloy.

| Operating parameters | HRT(hr) | MLSS(mg/ℓ) | DO(mg/ℓ) |

|---|---|---|---|

| Anoxic tank | 2.0 | 2,200 ~ 5,100 (3,200) | 0.1 or less |

| Aerobic tank | 4.0 | 4,120 ~ 7,240 (4,686) | 2.0 ~ 4.2 |

| Iron-aluminum elution tank | 0.14 ~ 0.35 (0.2) | - | 2.1 ~ 4.1 |

| Reactor tank | SRT: 10 ~ 30 days, F/M ratio: 0.09 ~ 0.2kg.BOD/kg.MLSS | ||

| Settling tank | Settling tank residence time 3 hours, water surface load: 14 ~ 20㎥/㎡ per day | ||

Configuration and function

| Process Name | Process Description | Effect |

|---|---|---|

| Anoxic tank |

|

|

| Aerobic tank |

|

|

| Nano alloy precipitation equipment |

|

|

| Final settling tank | Solid-liquid separation/sludge return/surplus sludge drawing |

|

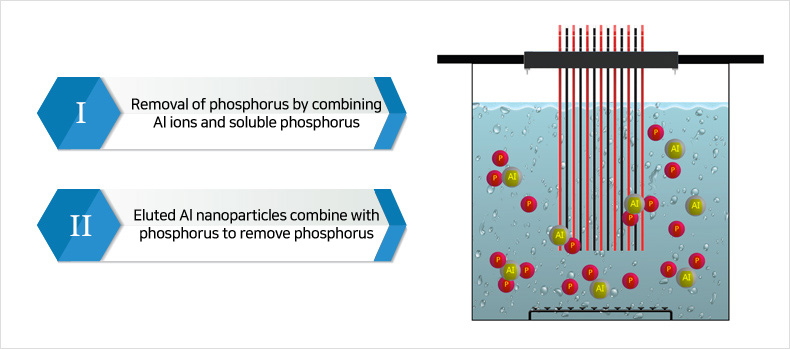

Phosphorus removal principle

- Precipitation of aluminum and nano ions

- Al ions are continuously deposited from the anode aluminum plate by passing a direct current through electrochemical dissolving action. - Phosphorus removal by physical reaction (mostly)

- Removal of phosphorus by physical reaction in which aluminum nanoparticles formed through bonding with precipitated aluminum ions are combined with oxygen and phosphorus and removed through settling. - Phosphorus removal by chemical reaction (partial)

- Removal of phosphorus by chemical reaction in which aluminum nanoparticles are combined with soluble phosphorus that is removed

Phosphorus removal mechanism

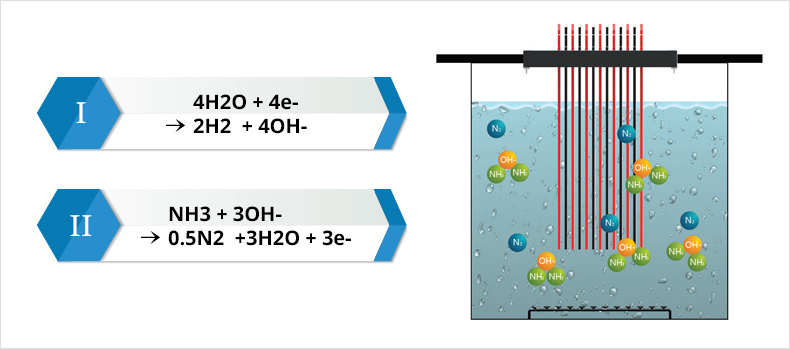

Nitrogen removal principle

- Ammonia removal

4OH- is generated.

2. Oxidation of ammonia by electrolysis

3. A large amount of ammonia is oxidized by oxidation of OH- radicals.

4. Ammonia decomposition is enhanced when salt is present.

5. Aluminum is eluted according to the Faraday method. - Denitrification

1. Aerobic tank : Nitration NH4+ + 2O2 -----> NO3- + 2H+ + H2O

2. Anoxic tank : Denitrification NO3-+6H++5e- 0.5N2+3H2O

Nitrogen removal mechanism

Processing efficiency

| Item | Influent concentration (mg/ℓ) | Discharge water concentration (mg/ℓ) | Removal rate (%) | |||

|---|---|---|---|---|---|---|

| Range | Average | Range | Average | Range | Average | |

| BOD | 85.8~133.6 | 105.0 | 6.3 ~ 9.9 | 9.0 | 89.4 ~ 93.0 | 91.4 |

| CODMn | 44.3~63.4 | 54.7 | 4.8 ~ 7.9 | 5.0 | 85.6 ~ 90.7 | 90.8 |

| SS | 76.9 ~ 101.7 | 93.8 | 7.5 ~ 12.0 | 7.5 | 87.6 ~ 92.3 | 90.2 |

| T-N | 29.8~36.4 | 33.2 | 9.3 ~ 11.8 | 9.2 | 65.8 ~ 73.1 | 72.2 |

| T-P | 2.64 ~ 3.05 | 2.87 | 0.16 ~ 0.23 | 0.19 | 95.4 ~ 98.5 | 93.3 |

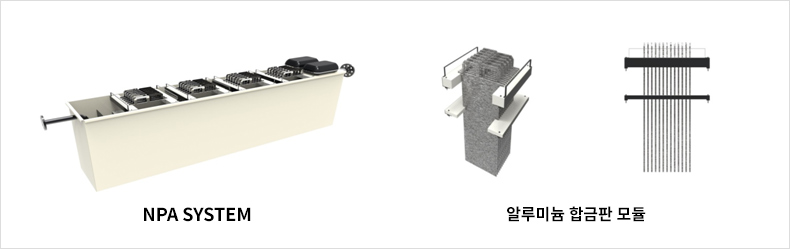

Design of NPA

Certification No.

- Patent No. 10-152877